RTCA/DO-160

RTCA/DO-160 Section 18: Audio Frequency Conducted Susceptibility – Power Inputs

Standard Overview

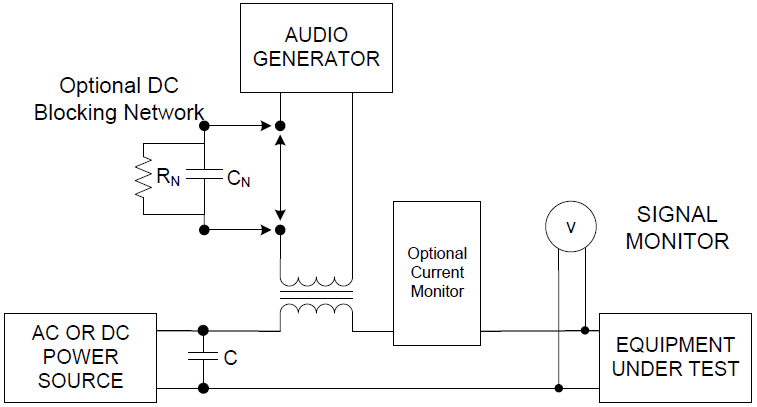

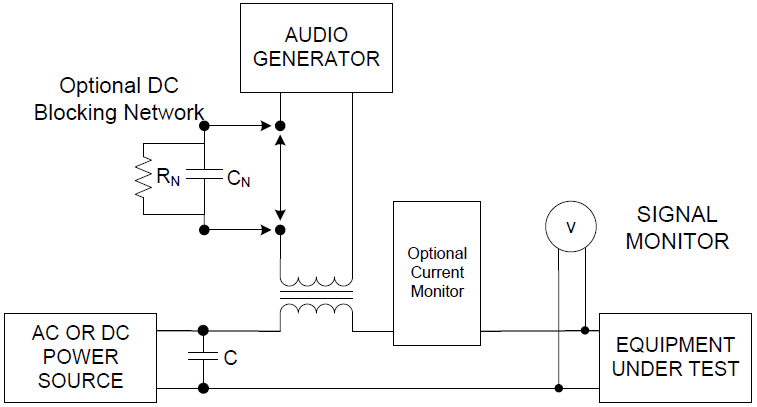

RTCA/DO-160 Section 18 provides test procedures to determine if the EUT will operate as specified when audio frequency interference is applied to the AC and/or DC power input. RTCA/DO-160 Section 18 is similar MIL-STD 461F test method CS101 with the only difference being test level and frequency range. The EUT must be tested while operating at both minimum and maximum current draw (if applicable), and at the AC power frequency extremes if designated for use with Variable Frequency systems when testing to RTCA/DO-160 Section 18 requirements.

Equipment Categories

There are three DC power Equipment Categories (R, B, and Z) that indicate the type of power used by the equipment and the type of DC power source with which the equipment is compatible.

AC Power Equipment Categories are specified as R and K. Category R is used with an additional designation (a two-character code), placed in parenthesis following the Category designator, indicates that the equipment has been tested for use with Constant Frequency (CF), Narrow Variable Frequency (NF), or Wide Variable Frequency (WF). Category K designates that the EUT has been tested for use with any type of AC power input, and tested to a higher level of voltage distortion than category R.

RTCA/DO-160 provides standard procedures and environmental test criteria for testing airborne equipment for the entire spectrum of aircraft from light, general aviation aircraft and helicopters through the "jumbo jets" and SST categories of aircraft. The tests outlined in this standard are performed to meet FAA and international regulations for electrical and electronic equipment installed on commercial aircraft.

RTCA/DO-160 G is the current version of this standard. Coordinated with EUROCAE, RTCA/DO-160G and EUROCAE/ED-14G are identically worded. DO-160G is recognized by the International Organization for Standardization (ISO) as de facto international standard ISO-7137.

Equipment Categories

There are three DC power Equipment Categories (R, B, and Z) that indicate the type of power used by the equipment and the type of DC power source with which the equipment is compatible.

AC Power Equipment Categories are specified as R and K. Category R is used with an additional designation (a two-character code), placed in parenthesis following the Category designator, indicates that the equipment has been tested for use with Constant Frequency (CF), Narrow Variable Frequency (NF), or Wide Variable Frequency (WF). Category K designates that the EUT has been tested for use with any type of AC power input, and tested to a higher level of voltage distortion than category R.

RTCA/DO-160 provides standard procedures and environmental test criteria for testing airborne equipment for the entire spectrum of aircraft from light, general aviation aircraft and helicopters through the "jumbo jets" and SST categories of aircraft. The tests outlined in this standard are performed to meet FAA and international regulations for electrical and electronic equipment installed on commercial aircraft.

RTCA/DO-160 G is the current version of this standard. Coordinated with EUROCAE, RTCA/DO-160G and EUROCAE/ED-14G are identically worded. DO-160G is recognized by the International Organization for Standardization (ISO) as de facto international standard ISO-7137.

Products Used in Testing

AE Techron 3110 Standards Waveform Generator

- DC-20kHz (DAC), DC-300kHz (Sine)

- 120VAC, 1.0VA service, 1Ø

- IEC 6100-4-16, ISO 7637, ISO 16750-2

AE Techron 7228 Linear Power Amplifier

- Frequency Range: DC – 1MHz

- AC Power: 1000W RMS

- Slew rate: 100 V/μs

AE-Techron 7796HC DC Power Amplifier

- Frequency Range: DC – 150kHz

- Max Power: 2,499W RMS continuous

- Slew Rate: 41V/µs

AE Techron T2000 Low-Frequency Conducted Susceptibility Transformer

- Frequency response: 10 Hz to 250 kHz.

- Turns ratio: 2:1 step down

- Audio power: 200W

AE Techron 7224 Linear Power Amplifier

- Frequency Range: DC – 300kHz

- Max Output Power: 1,100W RMS

- Slew Rate: 75V/µs

AE Techron 8704 Linear Power Amplifier

- Frequency Range: DC – 250kHz

- Max Power Output: <4kW continuous

- Slew Rate: <300V/µs

BOLAB Systems BLS-130-70N-TS 4-Quadrant Voltage Amplifier

- Frequency Range: DC – 1 MHz

- Max Output Power: 3,000 W

- For LV124 / VW80000, LV148, ISO 16750, ISO 7637, DIN 40839, GS 95024

AE Techron 7782 RMS Power Amplifier

- Frequency Range: DC – 50 kHz at full power

- Max Power Output: 3305 W RMS (2 Ω)

- Slew Rate: 40V/μs

AE Techron 7136 AC/DC Amplifier with Precision DC Power Supply

- Frequency Range: DC – 400kHz

- Max Power Output: 900W RMS (AC)

- Slew Rate: 165 V/µs

AE Techron 9110 Amplifier

- Frequency Range: DC – 250kHz (–3 dB)

- Max Power Output: 5kW

- Slew Rate: <300V/µs

AE Techron 7796 DC Power Amplifier

- DC – 30kHz (100kHz at reduced power)

- 22,000W peak (40mSec, 0.5Ω load)

- Slew Rate: 41V/µs

AE Techron 7794 4-Quadrant Power Amplifier

- Frequency Range: DC – 150kHz

- Max Power Output: 5,000W RMS (continuous)

- Slew Rate: 41V/µs

BOLAB 100-TS Series

- Frequency Range: DC – 1 MHz

- Output: 400 W – 18000 W

- For LV124/VW80000, LV148, ISO 16750, ISO 7637, DIN 40839, & GS 95024

AE Techron 8500 Series Amplifiers

- Bandwidth: DC - 50kHz

- Power: 4 - 20kW

- Slew Rate: 60V/µs