MIL

MIL-STD-461G CS117: Conducted Susceptibility, Lightning Induced Transients, Cables and Power Leads

Standard Overview

MIL-STD-461G CS117 applies to all safety-critical equipment interconnecting cables, including complete power cables, and individual high side power leads. MIL-STD-461G CS117 is also applicable to non-safety critical equipment with interconnecting cables/electrical interfaces that are part of or connected to equipment performing safety-critical functions. It may apply to equipment performing non-safety critical functions when specified by the procuring activity. MIL-STD-461G CS117 also has limited applicability to surface ship equipment which have cables routed above deck.

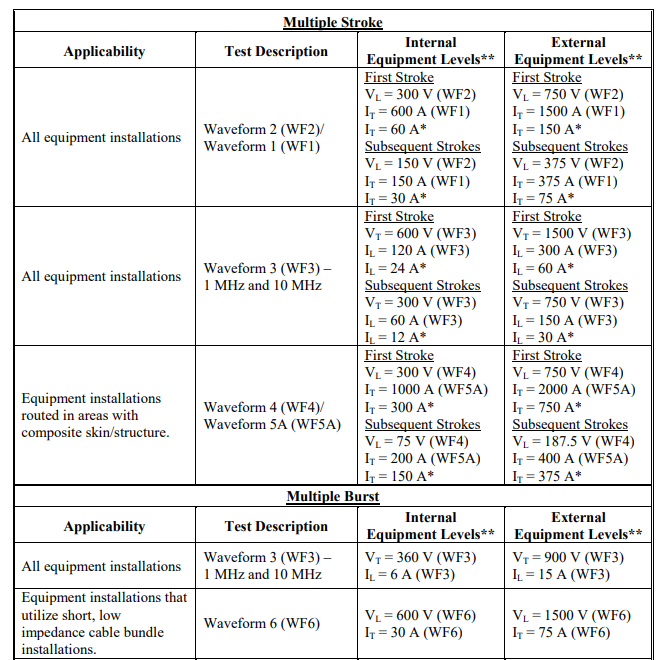

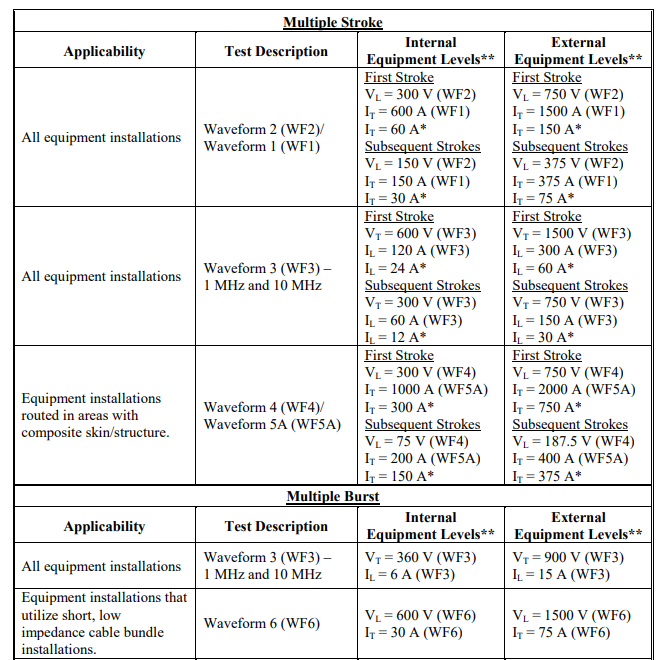

TABLE VII. CS117 Test and limit levels for multiple stroke and multiple burst lightning tests.

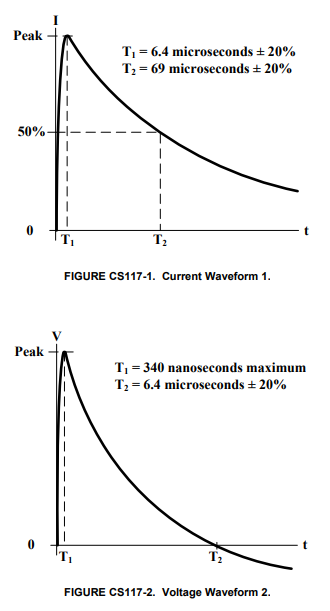

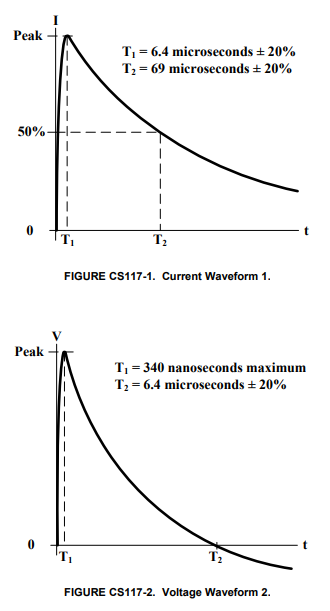

FIGURES CS117-1 Current Waveform 1 & CS117-2 Voltage Waveform 2

_20.png)

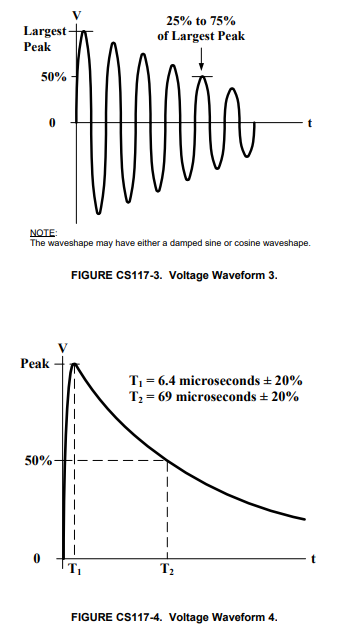

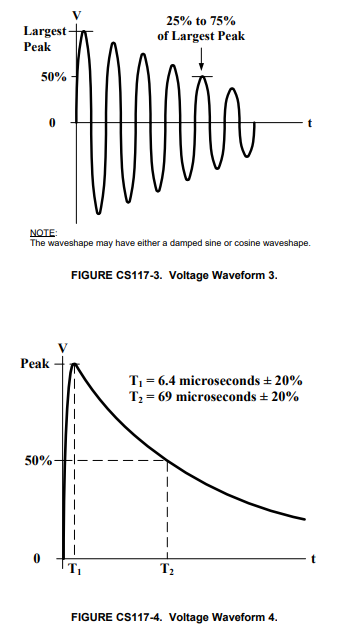

FIGURES CS117-3 Voltage Waveform 3 & CS117-4 Voltage Waveform 4

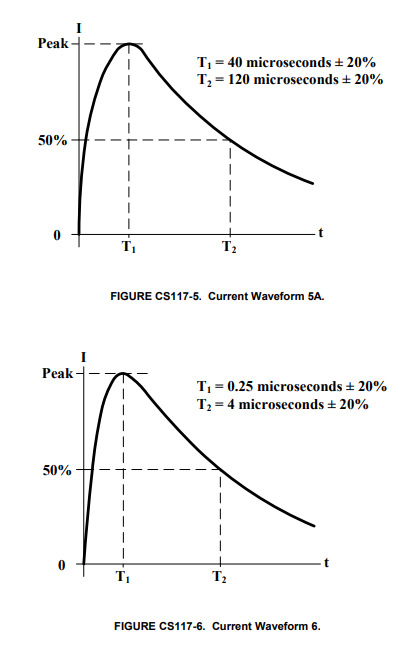

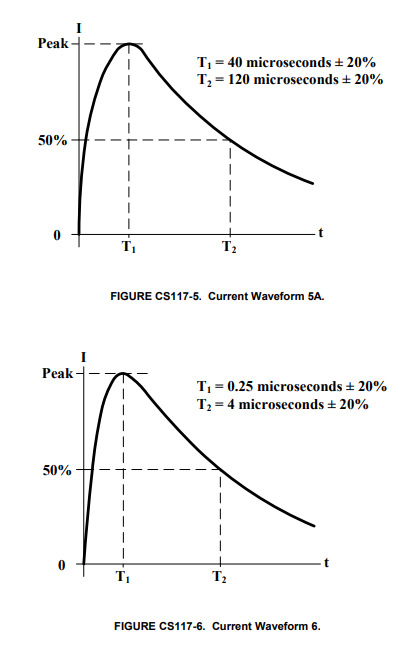

FIGURES CS117-5 Current Waveform 5A & CS117-6 Current Waveform 6

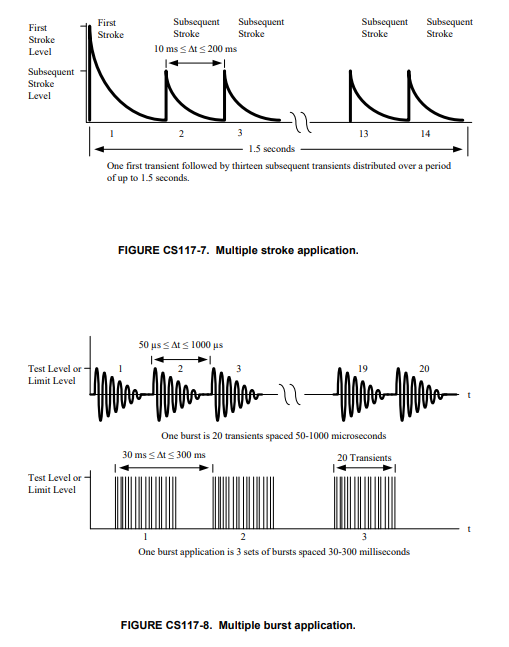

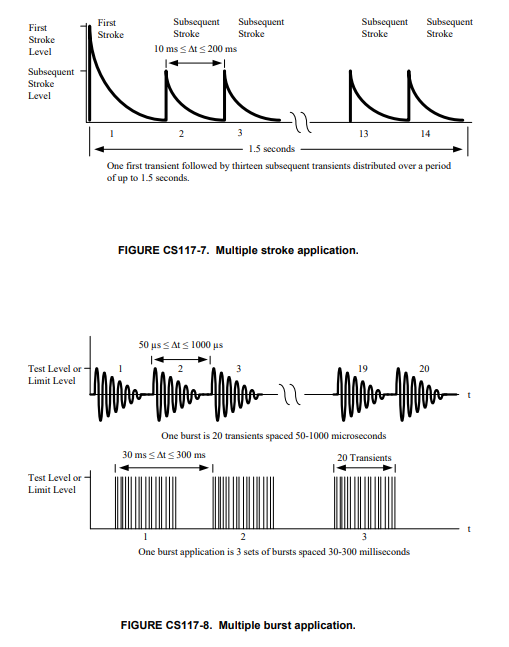

FIGURES CS117-7 Multiple stroke application & CS117-8 Multiple burst application

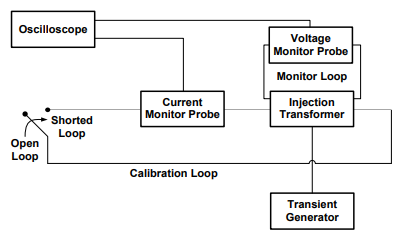

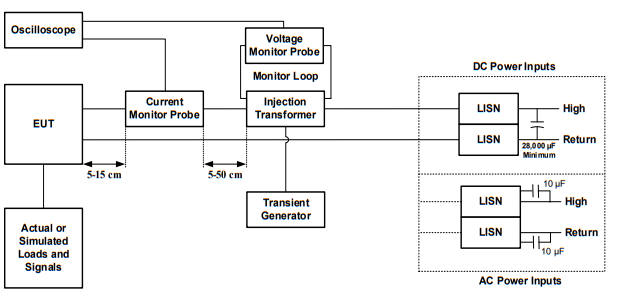

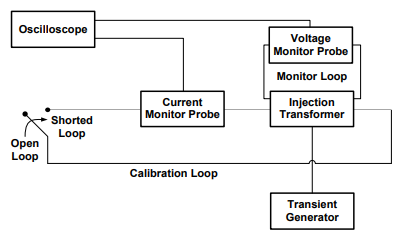

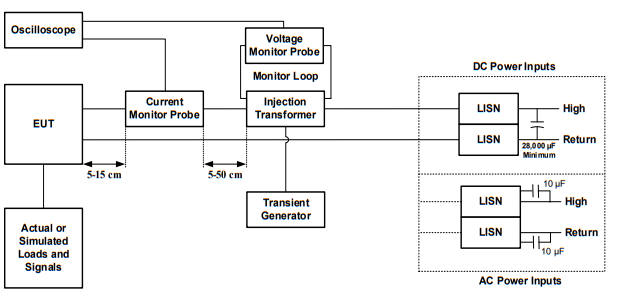

FIGURE CS117-9. Typical test setup for calibration of lightning waveforms.

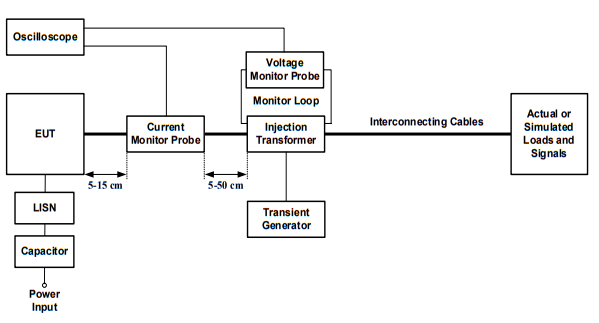

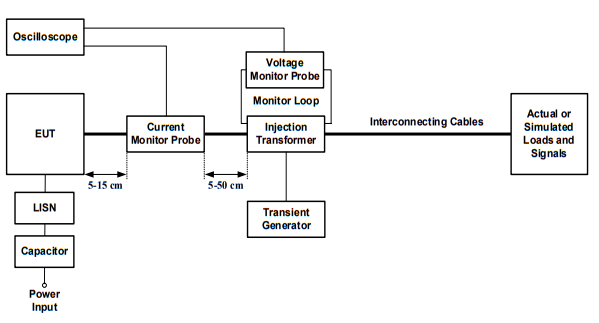

FIGURE CS117-10. Typical setup for bulk cable injection of lightning transients on complete interconnecting cable bundles.

_20.png)

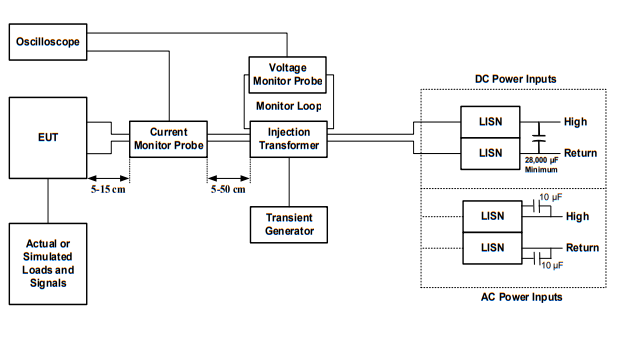

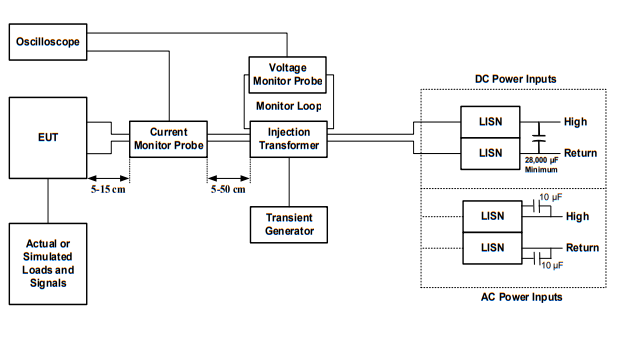

FIGURE CS117-11. Typical setup for bulk cable injection of lightning transients on complete power cables (high sides and returns)

FIGURE CS117-12. Typical setup for bulk cable injection of lightning transients on power cables with power returns and chassis grounds excluded from the cable bundle.

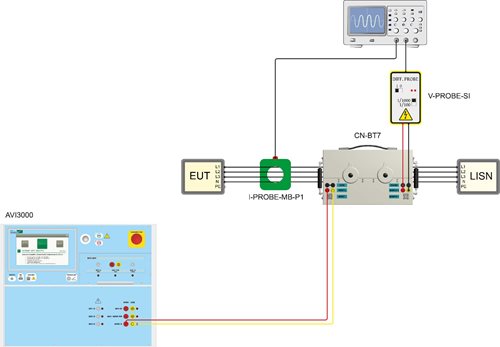

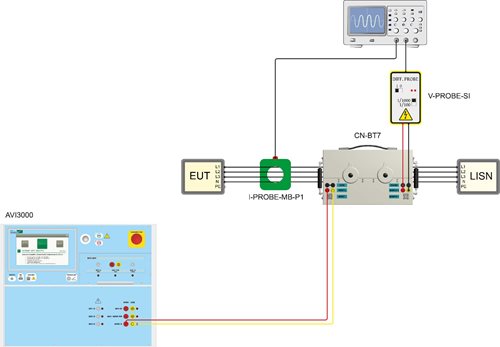

MIL-STD-461G CS117: Cable induction WF5A, MS, internal equipment, test setup

Test Equipment

- Lightning transient generator

- Injection Transformers

- Oscilloscope

- Current monitor probes

- Attenuators

- Voltage Probe

- LISNs

Procedures

The test procedures shall be as follows:- a. Turn on the measurement equipment and allow sufficient time for stabilization.

- b. Calibration. Perform the following procedures using the calibration setup for waveform verification.

- (1) Connect the transient generator to the primary input of the injection transformer.

- (2) For each waveform, at the designated test level (VT or IT), record the voltage waveform with the calibration loop open or the current waveform with the calibration loop shorted, as applicable. Verify that each waveform complies with the relevant waveshape parameters shown in Figure CS117-1 through Figure CS117-6. The transient generator doesn't need to produce the associated voltage or current limit level (VL or IL) and waveshape. However, if the transient generator is capable of reaching the designated limit level (VL or IL), record and verify the limit waveform at that generator setting.

- (3) For the Multiple Stroke and Multiple Burst tests, also verify the applicable pulse patterns and timing identified in Figure CS117-7 and Figure CS117-8.

- (4) Reverse the transient generator polarity and repeat 5.15.3.4b(2) through 5.15.3.4b(3).

- c. EUT testing.

- (1) Turn on the EUT and measurement equipment to allow sufficient time for stabilization.

- (2) While applying transients, increase the generator setting until the designated test level (VT or IT) or the limit level (VL or IL) is reached. Adjustments shall be made in the generator settings and/or injection transformer configuration as necessary to enable the required test level (VT or IT) to be achieved in the tested cable unless the corresponding limit level (VL or IL) is reached first. Calibration shall then be repeated if changes are made to the injection transformer configuration. Record the waveforms and amplitude levels obtained. If the limit level (VL or IL) is reached before the test level (VT or IT), the test shall be reevaluated to determine if the test is acceptable as follows:

- (a) If the transient generator produced a compliant limit waveform (amplitude and waveshape) during calibration, the test is acceptable.

- (b) If the specified limit waveform is achieved during the test and is within the waveshape tolerances shown in Figure CS117-1 through Figure CS117-6, the test is acceptable.

- (c) If one of the above criteria is not met, then the test shall be repeated for that cable bundle using another transient generator that can meet the limit waveform requirements. In this case, the associated limit level (VL or IL) now becomes the test level (VT or IT) and the test level now becomes the limit level. Calibration shall be repeated using the substitute transient generator.

- When measuring voltage or current waveform levels, short duration spikes or high frequency noise due to instrument noise, switching transients, or loading effects shall be ignored.

- (3) For the Multiple Stroke test, at the generator setting established in 5.15.3.4c(2), apply a minimum of ten multiple stroke applications while monitoring the operation of the EUT. The maximum time between application of each Multiple Stroke transient shall be no greater than 5 minutes.

- (4) For the Multiple Burst test, at the generator setting established in 5.15.3.4c(2), apply a multiple burst application every 3 seconds (3 seconds between the start of each set of three bursts) continuously for a minimum of 5 minutes.

- (5) Reverse the transient generator polarity and repeat 5.15.3.4c(2) through 5.15.3.4c(4).

- (6) Repeat 5.15.3.4c(2) through 5.15.3.4c(5) on each cable bundle interfacing with each electrical connector on the EUT. For power cables, perform 5.15.3.4c(2) through 5.15.3.4c(5) on complete power cables (high sides and returns) and on the power cables with the power returns and chassis grounds (green wires) excluded from the cable bundle. For connectors which include both interconnecting leads and power, perform 5.15.3.4c(2) through 5.15.3.4c(5) on the entire bundle, on the power leads (including returns and grounds) grouped separately, and on the power leads grouped with the returns and grounds removed.

Test Setup

The test setup shall be as follows:- a. Maintain a basic test setup for the EUT as shown and described in Figures 2 through 5 and section 4.3.8. The power input side of the LISN shall have a ≥ 28,000 µF capacitor between the high and return for DC power and a 10 µF capacitor from high and return to theground plane for AC power.

- b. Calibration. Configure the test equipment in accordance with Figure CS117-9 for verification of the waveform, both short-circuit current and open-circuit voltage.

- c. EUT testing:

- (1) Configure the test equipment as shown on Figure CS117-10, Figure CS117-11 or Figure CS117-12.

- (2) Place the injection transformer and current monitor probe(s) around a cable bundle interfacing an EUT connector.

- (3) Locate the current monitor probe 5-15 cm from the connector. If the overall length of the connector and backshell exceeds 15 cm, position the current monitor probe as close to the connector’s backshell as possible.

- (4) Position the injection transformer 5-50 cm from the current monitor probe.

- (5) Place a monitor loop in the injection transformer and connect a voltage monitor probe.

TABLE VII. CS117 Test and limit levels for multiple stroke and multiple burst lightning tests.

FIGURES CS117-1 Current Waveform 1 & CS117-2 Voltage Waveform 2

_20.png)

FIGURES CS117-3 Voltage Waveform 3 & CS117-4 Voltage Waveform 4

FIGURES CS117-5 Current Waveform 5A & CS117-6 Current Waveform 6

FIGURES CS117-7 Multiple stroke application & CS117-8 Multiple burst application

FIGURE CS117-9. Typical test setup for calibration of lightning waveforms.

FIGURE CS117-10. Typical setup for bulk cable injection of lightning transients on complete interconnecting cable bundles.

_20.png)

FIGURE CS117-11. Typical setup for bulk cable injection of lightning transients on complete power cables (high sides and returns)

FIGURE CS117-12. Typical setup for bulk cable injection of lightning transients on power cables with power returns and chassis grounds excluded from the cable bundle.

Calibration

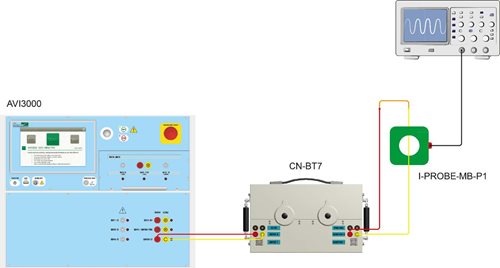

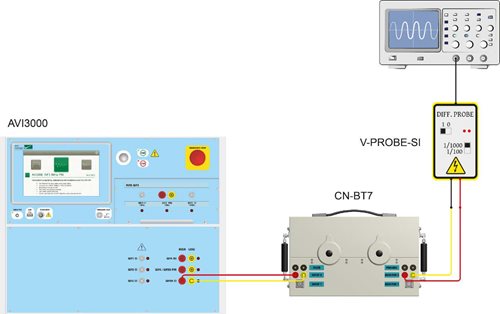

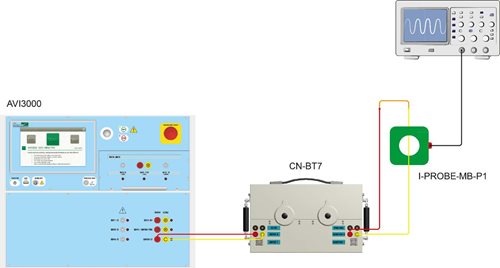

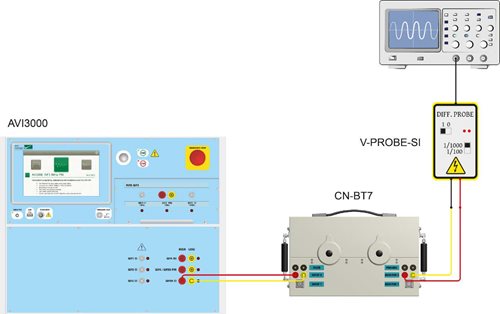

MIL-STD-461G CS117: Cable induction WF5A, MS , internal equipment, voltage and current calibration

MIL-STD-461G CS117: Cable induction WF5A, MS, internal equipment, test setup

Products Used in Testing

EMC Partner AVI3000 Indirect Lightning Generator for DO-160 and MIL-STD-461G

- Comfortable touchscreen menu - easy navigation

- All 6 waveforms in one unit

- Full level 3 threat under all load conditions

Solar 2654-2 Lightning Transient Generator System for DO-160

- The controller and power supply module

- Waveform timing

- The high voltage power supply

EMC Partner AVI-LV3 Indirect Lightning Generator

- RTCA/DO-160G S22

- MIL-STD-461G CS117

- Cable Induction (CI)

M Precision Laboratories ECAT Lightning Test System Level 5

- Quick test setup

- Simple user interface

- Single stroke, multiple stroke, multiple burst, and pin injection in the same front panel