What is Respirator Fit Testing?

Air respirator fit testers ensure that respirators are comfortable and provide the expected protection. They attempt to find any leaks or gaps that could cause harmful gases to enter an air respirator.

ATEC goes into their use cases and why they matter, as well as some solutions. Read more below.

.png) important, first we must understand how important it is for respirators to function properly. Air respirators are crucial for people working in contaminated areas. Respirators filter out gases, vapors, aerosols, and any form of contaminant in oxygen-filled environments.

important, first we must understand how important it is for respirators to function properly. Air respirators are crucial for people working in contaminated areas. Respirators filter out gases, vapors, aerosols, and any form of contaminant in oxygen-filled environments.

These devices are used in a plethora of industries, such as healthcare, aerospace, fire and emergency services, and much more. To make sure all workers in these industries can breathe safely under life-threatening conditions, it is important to make sure these respirators work properly.

.png) include:

include:

Passable fit factors depend on the type of respirator being tested. Half-mask respirators require a fit factor of at least 100, while full facepiece negative-pressure respirators require a minimum fit factor of 500.

Similarly to qualitative fit testing, there are protocols in place to test for fit factor. These include:

The most effective (safe) solution available today is the TSI PortaCount 8040 Respirator Fit Tester. It supports fit testing for full-face and half-face elastomeric respirators, as well as NIOSH Series-99/-100 and EN FFP3 filtering-facepiece respirators.

ATEC goes into their use cases and why they matter, as well as some solutions. Read more below.

Why are Air Respirator Fit Testers so Important?

To understand what makes air respirator fit testers so.png) important, first we must understand how important it is for respirators to function properly. Air respirators are crucial for people working in contaminated areas. Respirators filter out gases, vapors, aerosols, and any form of contaminant in oxygen-filled environments.

important, first we must understand how important it is for respirators to function properly. Air respirators are crucial for people working in contaminated areas. Respirators filter out gases, vapors, aerosols, and any form of contaminant in oxygen-filled environments. These devices are used in a plethora of industries, such as healthcare, aerospace, fire and emergency services, and much more. To make sure all workers in these industries can breathe safely under life-threatening conditions, it is important to make sure these respirators work properly.

What are the Types of Air Respirator Fit Tests?

Air respirator fit tests usually come in two forms, qualitative and quantitative. Both of these tests utilize the same seven core exercises to ensure normal breathing for a variety of circumstances. Those seven tests are:- Normal breathing

- Deep breathing

- Turning head side to side

- Moving head up and down

- Talking

- Bending over

- Normal breathing (again)

Qualitative Fit Testing

Qualitative fit testing (QLFT) is detected through the wearer’s taste, smell, and involuntary coughing. This testing relies on OSHA-accepted test agents to examine whether or not a person accurately senses the cartridges used for testing. Some of these cartridges.png) include:

include:

- Isoamyl acetate (banana-like smell)

- Saccharin (sweet taste)

- Irritant smoke (causes involuntary cough reflex)

Quantitative Fit Testing

Quantitative fit testing (QNFT) is performed by an instrument that measures those necessary values. Quantitative tests directly measure any leakage around the face, producing a numerical result known as the “fit factor” to judge whether the mask is safe.Passable fit factors depend on the type of respirator being tested. Half-mask respirators require a fit factor of at least 100, while full facepiece negative-pressure respirators require a minimum fit factor of 500.

Similarly to qualitative fit testing, there are protocols in place to test for fit factor. These include:

- Generated aerosol (non-hazardous aerosol, such as corn oil)

- Condensation nuclei counter (ambient aerosol)

- Controlled negative pressure (creates a vacuum to temporarily cut off air)

Industries Requiring Respirator Fit Testers

There is a plethora of industries that require people to use respirators. Pollutants come in all forms, and as such, require that respirators can accommodate each situation accurately. Below is a list of some industries that require respirator fit testers, and the danger presented in each one:- Healthcare & Hospitals: Toxic chemicals used for cleaning, sterilization, patient treatment, and laboratory work.

- Manufacturing & Industrial: Exposure to benzene, lead, asbestos, and more.

- Pharmaceutical & Biotech: Constant exposure to dangerous chemicals such as hydrochloric acid.

- Aerospace & Aviation: Exposure to chemicals, such as cadmium, toluene, xylene, and cellosolves

- Fire & Emergency Services: Smoke from fires can cause short-term irritation and long-term respiratory and cardiovascular issues.

Compliance Standards

These respirator fit testers are required to fit an assortment of standards, typically depending on what job they need to fulfill. Below is a list of regulatory compliance standards these testers fall under.Solution: TSI PortaCount 8040

Under most circumstances, the best solutions for respirator-related issues are either half-mask or full-face respirators with built-in filtration, which provide complete safety for those working in hazardous environments.The most effective (safe) solution available today is the TSI PortaCount 8040 Respirator Fit Tester. It supports fit testing for full-face and half-face elastomeric respirators, as well as NIOSH Series-99/-100 and EN FFP3 filtering-facepiece respirators.

PortaCount 8040 Overview

The TSI PortaCount 8040 Respirator Fit Tester is very user-friendly. Following the instructions (seen in the video below) ensures the masks you test will provide peace of mind with a completely safe fit the entire time they’re worn.

Request a Quote

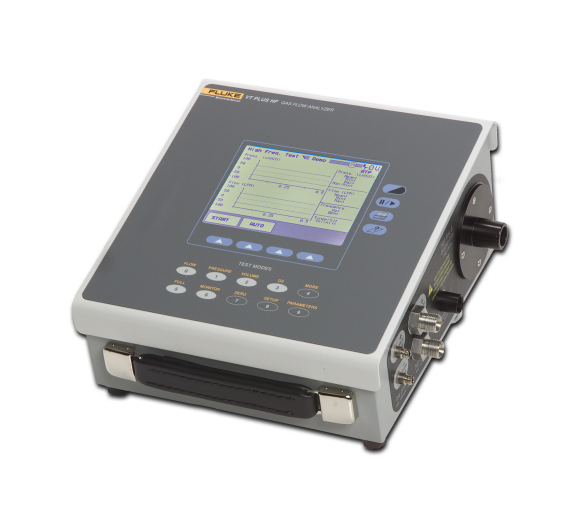

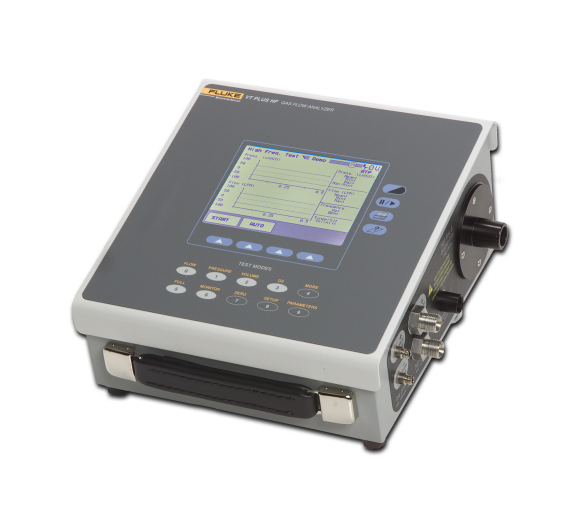

This video from TSI provides an excellent product overview.Additional Solutions: Fluke Biomedical VT PLUS HF

For those in the medical field looking for ways to also test ventilators ATEC also rents the Fluke VT PLUS HF to suit those needs. Although ventilators and respirators serve different purposes, both require fit testing to ensure oxygen flows to the user safely without outside interference. The VT PLUS HF can test both mechanical and high-frequency ventilators to keep oxygen flowing safely for medical patients.

Request a Quote

Posted April 15, 2025

.png)