MIL

MIL-STD-1275: Characteristics of 28 Volt DC Input Power to Military Vehicles

Standard Overview

MIL-STD-1275 is a military test standard that defines nominal 28 VDC voltage characteristics that are common to all military ground vehicles, specifically at the input power terminal of electronic/electrical assemblies that are directly connected to the distribution network in question. MIL-STD-1275 establishes a framework for similarity throughout military vehicle platforms. Design authorities are charged with making sure the 28 VDC applied to the input power terminal of the equipment meets MIL-STD-1275 requirements. This standard does not relate to power sources or power systems, but instead focuses on utilization equipment and required operating conditions.

5.1.1 Steady-State Operation

5.1.3 Transient Disturbances

5.2.1 Environmental Conditions

5.2.2 Calibration of Test Equipment

5.3.1 Steady-State Operation

Figure 9

Figure 10

Figure 11

Figure 4

Table 1

Download Standard

General Requirements

Reverse Polarity

Utilization equipment is required to defend itself against damage caused by input power with reverse polarity; the magnitude of the reverse polarity input current should be equal to or less than the magnitude of the utilization equipment normal operating current, with reverse polarity voltage applied to the input power terminals of the utilization equipment.Electromagnetic Compatibility

Utilization equipment should be compatible with relevant performance specification requirements for the mitigation of electromagnetic interference, electromagnetic pulses, power switching, and lightning-induced voltage spikes. (Electromagnetic interference is not covered by MIL-STD-1275).Electrostatic Discharge

Utilization equipment must be compatible with applicable performance specification requirements for electrostatic discharge (ESD) immunity. (Electrostatic discharge is not covered by MIL-STD-1275).Detailed Requirements

Voltage Compatibility Requirements

The first section of MIL-STD-1275's requirements, section 5.1, offers detailed requirements for the voltage conditions under which the device under test is intended to operate.5.1.1 Steady-State Operation

- Operating voltage range: between 20 VDC and 33 VDC, including ripple (max. peak-to-peak ripple limits specified in MIL-STD-461 CS101).

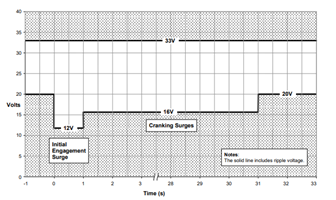

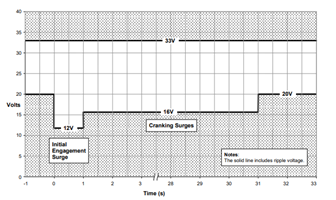

- Equipment should operate without damage when experiencing engine starting disturbances within the limits in Figure 6.

- Initial engagement surge (IES): 12 VDC, with max. duration as 1 second.

- Cranking surge: min. voltage supplied is 16 VDC, max. duration of cranking surges is 30 seconds.

5.1.3 Transient Disturbances

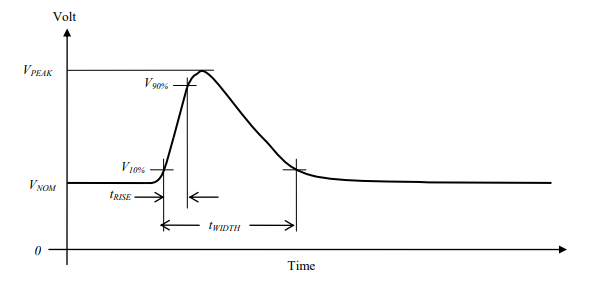

- Voltage Spikes

- Injected Voltage Spikes

- Max. rise time of injected spikes: 50 nanoseconds.

- Max. total energy content of single spike: 2 Joules.

- Emitted voltage spikes

- Max. energy content of emitted spike: 125 millijoules (mJ).

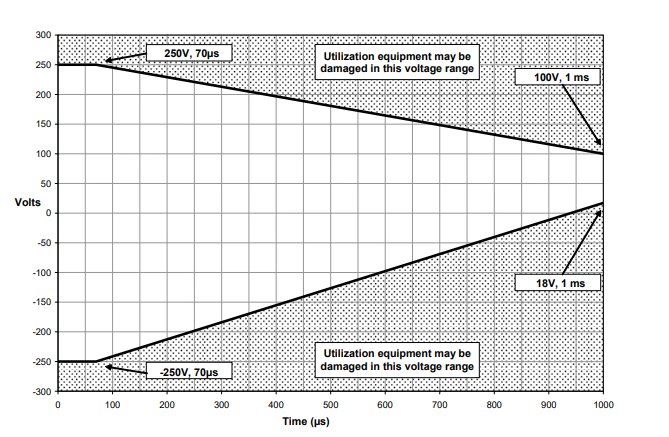

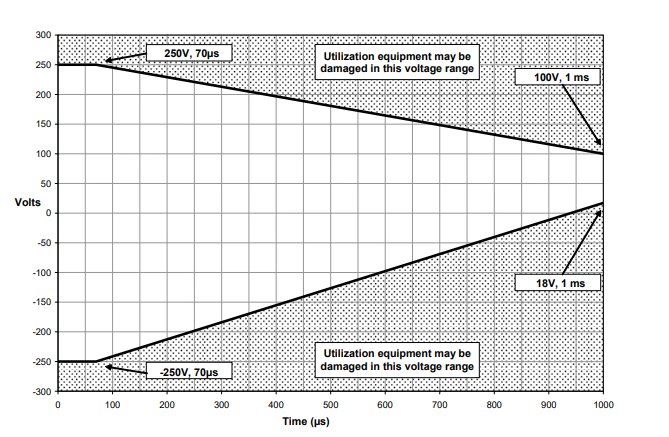

- Equipment should operate without damage when experiencing voltage spikes within the limits in Figure 7.

- Injected Voltage Spikes

- Voltage Surges

- Emitted Voltage Surges

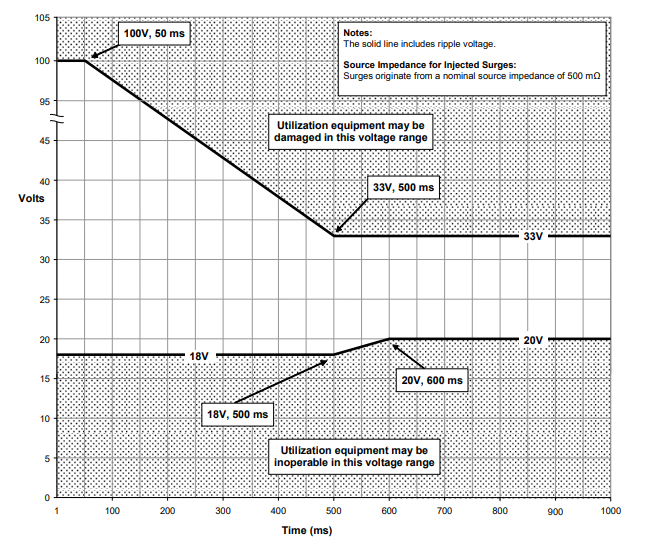

- Emitted voltage surges from the equipment should be within limits in Figure 8.

- Injected Voltage Surges

- Max. energy content of a single surge is 60 Joules.

- Equipment should operate without damage when experiencing voltage surges within the limits in Figure 8.

- Emitted Voltage Surges

Voltage Compatibility Verification Setup

The second section, 5.2, details the setup for voltage compatibility verification testing.5.2.1 Environmental Conditions

- The following are the environmental conditions under which the testing of the DUT should be performed:

| Temperature | +23°C ± 5°C (+73°F ± 9°F) |

| Relative Humidity | 0% to 90% humidity |

| Atmospheric Pressure | 80kPa to 102kPa (23.62 inHg to 30.12 inHg) |

5.2.2 Calibration of Test Equipment

- Any test equipment used to verify voltage, current, rise/fall time, etc. of the setup should have a NIST traceable calibration or equivalent calibration certificate from a national standards body.

- ±1%

- Power input terminals.

- A power return should be used as called for by the applicable performance specification; if a power return is not specified, the DUT return conductor should match the DUT power source conductor.

- If the DUT is not a standalone, representative loads for the actual vehicle installation should be used.

- Power supplies should maintain ±1% of voltage during testing, as measured at output.

Voltage Compatibility Verification Method

The final section of MIL-STD-1275's requirements discusses the method for performing voltage compatibility verification.5.3.1 Steady-State Operation

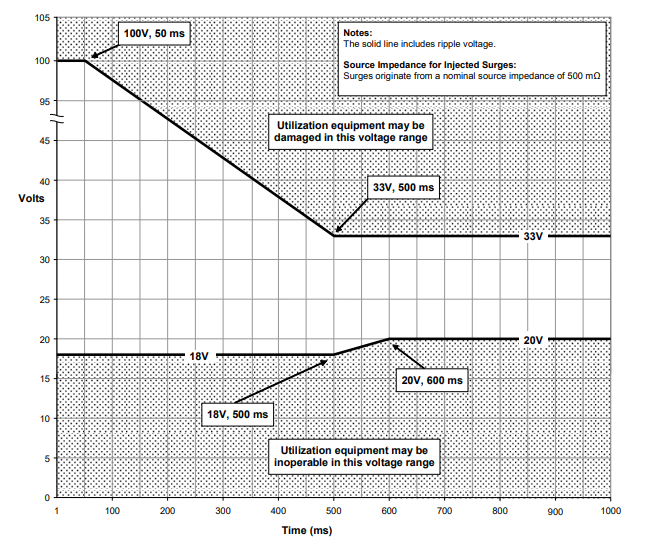

- The DUT should be tested to operate as depicted in the lower and higher limits of the voltage envelope shown in Figure 8.

- Voltage ripple: the test method and limits specified by MIL-STD-461 CS101 shall be used at nominal voltages of 23 VDC and 30 VDC with the same values used at 150 kHz extended to 250 kHz, as shown in Figures CS101-1 and CS101-2.

- The DUT should be tested to operate within the lower limit of the voltage envelope shown in Figure 6.

- Voltage Spikes

- Injected Voltage Spikes

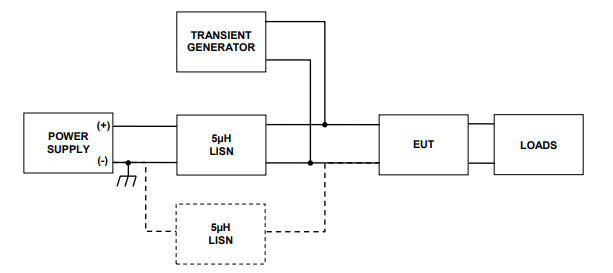

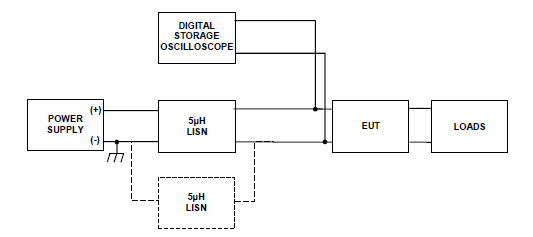

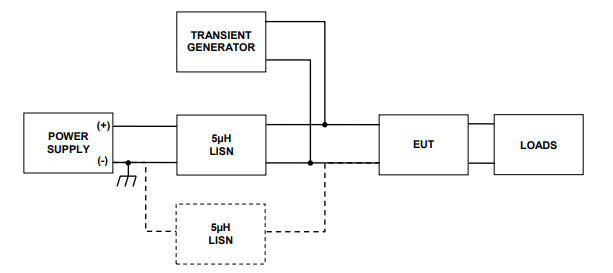

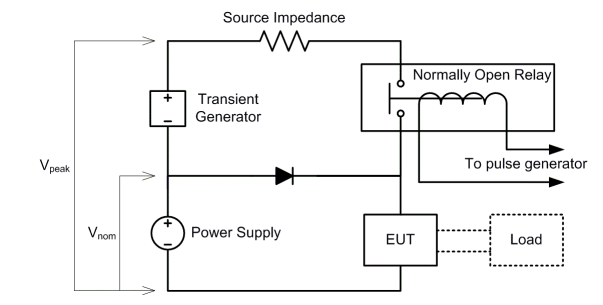

- The DUT should be given power by a voltage source set to 28 VDC through a LISN, and the test operator should inject voltage spikes into the DUT using a setup similar to the one depicted in Figure 9.

- Power return is the vehicle chassis: 1 LISN.

- Dedicated power return conductor: 2 LISNs.

- Voltage spikes: min. 50 250V of each polarity, applied at 1-second intervals, peak amplitude of 250V, rise time not greater than 50 ns, oscillation frequency greater than 100 kHz and below 500 kHz, max. energy content of 2 Joules.

- Emitted Voltage Spikes

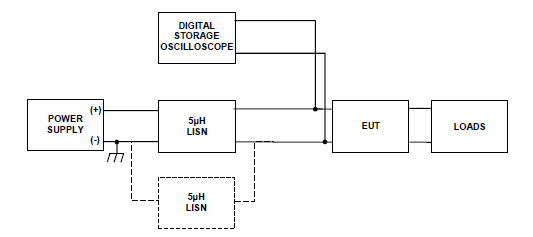

- The DUT should be supplied power by a source set to 28 VDC operating voltage. Use the test method specified in SAE J1113-42 to measure spikes with the setup in Figure 10.

- Power return is the vehicle chassis: 1 LISN.

- Dedicated power return conductor: 2 LISNs.

- Switching function: should be exercised min. 32 times to ensure max. voltage spike is recorded.

- Voltage spikes: any spike or combination of spikes should have any energy content less than 125 mJ.

- Spikes should be within limits of Figure 7.

- Injected Voltage Spikes

Figure 9

Figure 10

- Voltage Surges

- Injected Voltage Surges

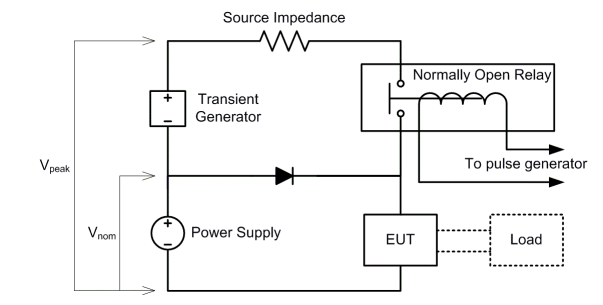

- Inject voltage surges into the DUT using a setup as shown in Figure 11.

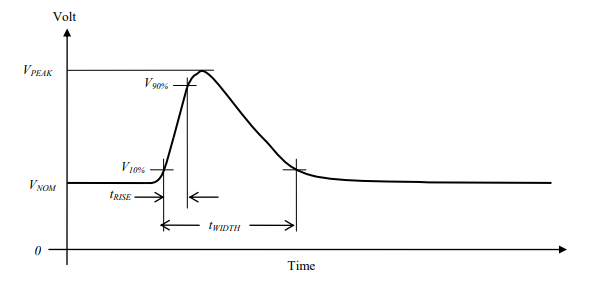

- The waveform injected on the power lines of the DUT should simulate the voltage surge seen in Figure 4.

- Voltage surge parameters can be seen in Table 1.

- The energy emitted from the transient surge generator should be limited to 60 Joules.

- Before connecting the DUT, the operator should verify the amplitude and duration of the voltage surge specified in Table 1.

- Emitted Voltage Surges

- The DUT should be supplied power by a source set to 28 VDC operating voltage.

- Measure voltage surges with a setup like Figure 10.

- Surge function: should be exercised min. 32 times to ensure max. voltage spike is recorded.

- Voltage surges should be within methods in Figure 8.

- Injected Voltage Surges

Figure 11

Figure 4

Table 1

| Operating Voltage | Amplitude | Rise Time | Duration | Source Impedance | Number of Pulses | Time Between Pulses |

| 30 -0/+1 V (nominal) | 100 -0/+10 V (peak) | 1 < t < 10 | 50 -0/+5 | 500 -25/+0 | 5 | 5 |

- 5.3.5 Electromagnetic Compatibility

- Not covered by this standard.

- 5.3.6 Electrostatic Discharge

- Not covered by this standard.

Testing to MIL-STD-1275D with the montena PG1275

Download Standard

Products Used in Testing

Montena PG1275 Surge Generator

- Standard: MIL-STD-1275D

- Transients supported: imported and exported spikes imported and exported surges

- imported and exported spikes

Montena PG1275E Surge Generator for MIL-STD 1275E

- Generator can be fully controlled by a computer through a RS232 or an USB interface

Sorensen SGI60/83C Precision Programmable DC Power Supply 60V, 83A

- Voltage: 60V

- Amperage: 83A

- Phase: 3Ø

Montena PG1275F Surge Generator

- 16A max. (400A - DM400 Diode)

- Injected voltage spikes, injected voltage surge

- < 45 mΩ (DC) + 300 µH