Fiber Testing

What Is Fiber Testing?

Fiber testing refers to the certification, troubleshooting, inspection, and splicing test methods applied to fiber optic cabling. For fiber cables, plants, and networks across the world, these tests are essential for verifying performance.

As the primary medium for facilities, data centers, and campus networks, fiber optic testing is an essential safeguard for the digital communications industry. Though these cables are capable of transferring mass amounts of data quickly and efficiently, they require rigorous testing to ensure these bandwidths and speeds. Acquiring the correct equipment to perform these tests is essential for cable maintenance.

This page covers the basics of how to test fiber optic cable, the various methods and steps of the fiber testing process, and some of the most common standards.

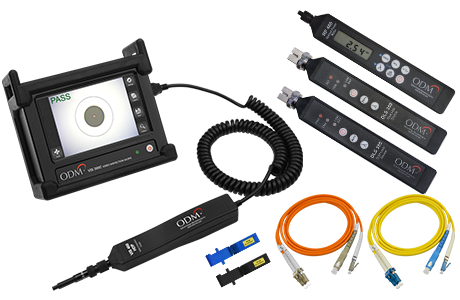

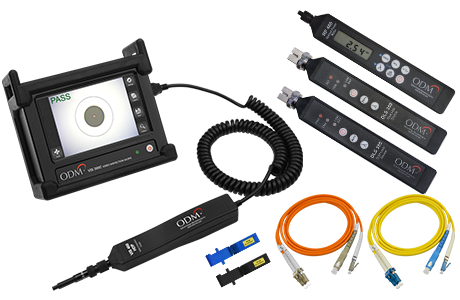

Watch this short video for fiber optic inspection and testing basics when using an ODM TTK 650:

Fiber optic cabling also requires inspection and cleaning to guarantee the proper passage of light, even when brand new. Oil, dust, and other contaminants may be deposited on fiber by a simple touch and distort the attenuation once a connection is made. This leads to slower transfer speeds and possible permanent damage. Fiber inspection kits, like the ODM TTK 650 in the video above, verify the fiber is clean and ready to connect.

When re-routing fiber connections to accommodate for wired network design changes, fusion splicers are necessary. A fusion splicer will split a cable and melt two cables together to allow for new fiber connections without sacrificing cabling or incurring light loss.

Fiber testing methods can be as straightforward as 1-2-3.

View More Products

View More Products

More information can be found on What is OTDR Testing?

View More Products

View More Products

View More Products

This page covers the basics of how to test fiber optic cable, the various methods and steps of the fiber testing process, and some of the most common standards.

Watch this short video for fiber optic inspection and testing basics when using an ODM TTK 650:

How to Test Fiber Optic Cable

Once a new fiber cable infrastructure is installed, the cabling needs to be tested and certified to various standards depending on which applications the link is intended to run. Fiber certifiers, or optical loss test systems (OLTS), measure the absolute loss of the link as compared to standardized loss limits. Troubleshooting is then performed with an optical time domain reflectometer (OTDR), which detects light reflected from bends or other faults in the fiber.Fiber optic cabling also requires inspection and cleaning to guarantee the proper passage of light, even when brand new. Oil, dust, and other contaminants may be deposited on fiber by a simple touch and distort the attenuation once a connection is made. This leads to slower transfer speeds and possible permanent damage. Fiber inspection kits, like the ODM TTK 650 in the video above, verify the fiber is clean and ready to connect.

When re-routing fiber connections to accommodate for wired network design changes, fusion splicers are necessary. A fusion splicer will split a cable and melt two cables together to allow for new fiber connections without sacrificing cabling or incurring light loss.

Fiber testing methods can be as straightforward as 1-2-3.

Fiber Testing Methods

Before certification, a fiber optic inspection kit performs end-face inspections and cleaning. Next is Tier 1 certification, testing for optical loss and power. Following that is Tier 2 certification, in which light reflected by the fiber is detected for quality testing and troubleshooting using an OTDR. Tier 1 certification must be completed to perform Tier 2 certification. Other types of equipment include fusion splicers, used to join two fibers together; and IP network testers, which test and troubleshoot wired and wireless networks. There are also fiber testers, which is a catch-all term for equipment that can perform one or more tests.Step 1: Fiber Optic Inspection

The first step of testing, inspection and cleaning kits perform end-face inspections and fiber cleaning with an optical power meter. Fiber should be cleaned whenever an end face encounters a possible contaminant; common contaminants include water, oil, and dust. Because the cables are so fine, end-face contamination even from a fingertip disrupts the flow of light and causes network outages and downtime. Inspection and cleaning are performed when splicing, certifying, or troubleshooting fiber cables.

View More Products

Step 2: Fiber Certifiers/OLTS

Fiber certifiers, also known as optical loss test systems or OLTS, perform certification tests on fiber optic cables. A fiber certifier determines if light passes through fiber cabling in compliance with IEEE, TIA/EI, and ISO/IEC standards. Fiber certifiers fall under Tier 1 testing and come either as a light source to be used with a separate power meter, or as a single unit with both functionalities and certification software. The following product is recommended for fiber certification:

View More Products

Step 3: OTDRs

An OTDR, or optical time domain reflectometer, is designed for troubleshooting fiber optic cables under Tier 2 testing. OTDRs characterize fibers and detect bends, breaks, or distortions by measuring the length and forming a picture, or trace, of the cable’s condition. OTDRs create these traces by sending pulses of high-powered laser light down the fiber and measuring the light that bounces back (backscatter). A trace should be taken of the cable at first installation for immediate verification and for future reference.More information can be found on What is OTDR Testing?

View More Products

Fusion Splicers

Fusion splicers fuse two fiber optic cables together into a single long fiber using an electric arc. This results in two permanently joined glass fibers from end to end with very little loss, so optical light signals can pass through from one fiber to the other. These devices provide displays which allow technicians to visually inspect the fusion splice to identify it as a good or bad splice. Splice quality depends on whether a flaw is detected and, if the flaw does not affect the optical transmission, the type of flaw.

View More Products

IP Network Testers

IP network testers include wired and wireless testers. Wired network testers, also called active network testers, are designed for performing fiber network testing. A wired network tester quickly certifies two fibers concurrently over two wavelengths and troubleshoots work and measurements. Wireless network testers troubleshoot copper, fiber optic, and Wi-Fi networks, offering a view of network performance ideal for resolving connection problems and completing deployment projects.

View More Products

Fiber Optic Test Standards

Fiber testing equipment from ATEC ensures that cabling meets IEEE, TIA/EI, and ISO/IEC standards. The following are common test standards to which tests like optical loss and back reflection tests are performed:- ANSI/TIA-568-C.3 | Optical Fiber Cabling Components

- ANSI/TIA-568.1-D | Commercial Building Telecommunications Cabling

- AEN 134 | OTDR Testing – Basic

- AEN 135 | Fiber Optic Testing Procedure

- ANSI/TIA/EIA 526-7 | Measurement of Optical Power Loss